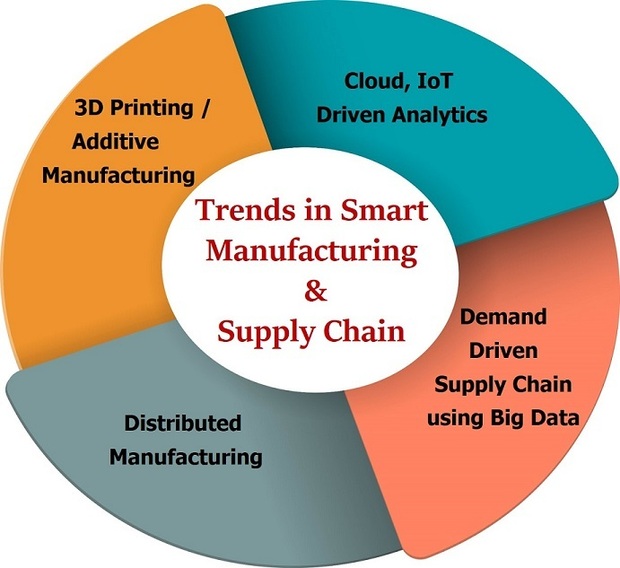

4 Key Trends to Watch in Smart Manufacturing and Supply Chain

Author: Raman Mehta

Industrial IoT and big data are converging to enable demand-driven ‘smart supply chains.’ The advancements in 3D printing and ‘Additive Manufacturing,’ coupled with supply chain efficiencies, could make distributed manufacturing a reality.

I remember reading an MIT paper on manufacturing technology trends a couple of years ago. It had a fascinating mention of “Additive Manufacturing” (AM) and how it could be a game changer. One of the biggest challenges facing automotive, aerospace and defense manufactures is the limited shapes a part can be cut, molded or welded in. On the other hand, a digitally 3D-printed part can be molded into an infinite number of shapes. According to industry standard ASTM F2792-10, AM is defined as, “The process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing technologies.”

(Key trends in smart manufacturing and supply chain)

The promise of AM is the use of less material, lightweight alloys and to provide faster cycle time due to rapid prototyping. The AM processes would produce less scrap, address complex geometries and improve strength-to-weight ratios. AM has the potential to move manufacturing from mass production in large factories with dedicated machining and tooling lines to an era of mass customization and distributed manufacturing.

It would be interesting to watch how AM matures in the years to come, because it is still in early stages. AM cost centers are currently more expensive than traditional CNC machining, and the production rate is slower once you move past the rapid prototyping phase. The powdered material availability and suitability in a variety of industrial applications is still evolving. The mechanical properties of the parts produced with AM have to be proven. It is especially important in the industries such as automotive, aviation and energy, where failure of a part has direct safety implications.

The next key trend I see coming is a more prominent role of Internet of Things (IoT) in extended supply chains. IoT can help companies provide improved predictability of customer demand with real time visibility of product and service demand signals. In a global supply chain, strategic deployment of IoT technologies can improve asset utilization, customer service, working capital deployment, waste reduction and sustainability. Real time communication between machines, factories, logistic providers and suppliers provides improved visibility on the end-to-end supply chain.

IoT can address compliance, regulatory and quality reporting requirements such as parts traceability and product genealogy, emissions and country of origin. With IoT, organizations are better suited to track shipped products for warranties, returns and predictive support for maintenance.

The real premise of IoT-enabled supply chains is to delegate decision making on some of the operational aspects to smart objects and systems, based on real time analytics and machine learning algorithms.

One of my concerns is IoT security — especially on how to protect deeply embedded end-point legacy devices that have limited resources and interfacing mechanisms available

(Value drivers for smart manufacturing and supply chain)

This brings us to customer- and market-driven supply chains. Most companies think they do their supply chain planning based on the demand— in reality most of the time it is nothing but a disguised forecast based supply chain. To gain and sustain competitive advantage, the principles of lean manufacturing, just in time and inventory control are simply not enough. Organizations would need to be not only aligned with true customer demand but also shape the demand using technology and analytical tools.

Supply chains need to move away from being forecast driven to become demand driven. Forecasts by their very nature are inaccurate. You cannot simply go by historic sales patterns, throw in current market conditions and seasonality, and hope for the best. One needs to shape the demand, the goal needs to be maximization of the profit, not simply reduction of cost or maximization of revenue. The essence of demand shaping is knowing about your most profitable customers and products, and protecting and promoting them.

All customers are not created equal. The data science algorithms can help in customer segmentation and clustering. They can tell which customers are the lowest cost to serve and which are likely to buy the highest profit products. The current crop of big data and analytics tools provide a way to integrate data from sales, marketing, action of customers, product reviews, competitor information, warranty data and supplier status in near real time to make demand driven supply chains a reality.

Big data can help in capturing structured and unstructured data from sources internal, as well as external, to the enterprise. Big data now enables “postponement”— a practice that allows manufactures to delay building final finished products until the very last possible moment, to be truly sensitive to customer demand.

This leads us into our final trend of distributed manufacturing. There have been opposing trends of strategic outsourcing of manufacturing versus bringing more and more manufacturing in-house. The first approach provides flexibility, frees up capital resources, lowers cost and speeds up product development. The inherent risk with the outsourcing approach is the potential to lose intellectual capital, lack of control on the process and quality, and the potential of brand dilution.

Strategically-distributed manufacturing is the future of manufacturing. In the next few years, Industry 4.0 will bring advances in AM, IoT enabled connected factories, manufacturers and distributors, and end consumers will make distributed manufacturing a reality.

Source: CIO.COM

You may interest: SCM Future Trend – Big Data & IoT application